DELTA Alloys & Metals Handheld XRF Analyzers provide highly specific material chemistry to rapidly and accurately identify alloy grades and pure metals. Get alloy chemistry and grade ID in seconds, from simple sorting to challenging grade separations, from incoming material inspection to end-product verification.

Configured with a standard package of 25+ elements, the DELTA generates alloy chemistry and grade ID in seconds. From simple sorting to challenging grade separations, the DELTA provides highly specific material chemistry to rapidly and accurately identify pure metals and alloy grades including, but not limited to:

| Aluminum alloys | Precious metals |

| Chromium-Molybdenum steels | Stainless steels |

| Cobalt alloys | Tool steels |

| Copper alloys | Titanium alloys |

| Exotic alloys | Wrought Aluminum alloys |

| Magnesium alloys | Zinc alloys |

| Nickel alloys | Zirconium alloys |

| Nickel/Cobalt alloys |

When you need a reliable analysis tool to provide fast and accurate Positive Material Identification (PMI), turn to the DELTA. From turnings, shavings, rods, and wires to small parts and components, to more sizeable material or structures, the DELTA provides anywhere, anytime testing with faster and more accurate results than ever before.

Easily and directly sorts and grades Aluminum and Aluminum containing materials. The DELTA Premium offers unmatched Al performance.

3 Mm Spot Collimation For Weld Bead Exclusive Of Joined Material

3 Mm Spot Collimation For Weld Bead Exclusive Of Joined Material

Small Spot Collimation For PCB Component Analysis

Small Spot Collimation For PCB Component Analysis

DELTA Analyzers can be equipped with 3mm diameter spot collimation for hightly focused sample analysis. An integrated full VGA camera takes live video image of the sample tested and superimposes a spot location for precise test location. Capable of analyzing thin weld beads independent from substrate materials. Analyzes small fixture components, wires and solders.

Weld Mask Adaptor

DELTA Premium Alloy Analyzer

with Weld Mask installed

The ruggedized weld mask can be attached to the front plate of the snout to collimate analysis to a 3 mm width slot, which is perfect for rapid, on-site weld bead analysis. The DELTA weld mask is engineering with layered metals to exclude substrate materials from analysis.

The DELTA is a reliable and rugged analyzer that maximizes both speed and accuracy. Other XRF systems have trade-offs. They may be able to identify alloys quickly, however inexperienced operators may not be able to determine whether an ID is incorrect, or whether longer testing is required. So how does the conscientious inspector maximize testing speed without increasing the risk of mistaken IDs or erroneous readings? Innov-X's SmartSort solution automates all these decisions, enabling even inexperienced operators to maximize both speed and inspection accuracy. This powerful feature yields optimized throughput and accuracy, making the DELTA an extremely productive XRF for alloy inspection.

Superior Light Element Analysis

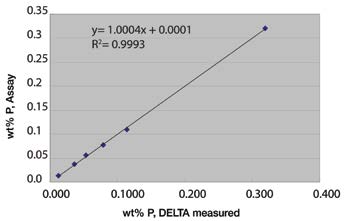

Traditionally a difficult area for handheld XRF, the analysis of light alloys and elements (Mg, Al, Si, P, S) can now be routine with the DELTA Alloy and Metal XRF Silicon Drift Detector (SDD) Analyzer with the newly available X-act Count Technology. Its integration with a 40kV Rhanode tube and automatic filtering provides fast, precise analysis of transition and heavy metals, and sensitive measurement of light element content. SmartSort maximizes testing throughput - sample by sample, testing is automatically extended or terminated - maximizing accuracy and throughput.

Correlation plot of Phosphorus (P) in Low Alloy Steel Analysis by DELTA Premium SDD Analyzer.

DELTA SDD Analyzer Benefits

The DELTA is engineered to be utilized for in-service inspection of high temp systems with temperatures in excess of 426oC (800oF)

Analysis Results Display Demonstrating Nominal Value (3% Al) And Tramp Element (0.09% Fe) Features.

Analysis Results Display Demonstrating Nominal Value (3% Al) And Tramp Element (0.09% Fe) Features.

| Excitation Range | DELTA Professional | 4W Ag, Rh, Au, or Ta anode (per application) X-ray tube |

|---|---|---|

| DELTA Element | 2W Au anode X-ray tube | |

| Detector | DELTA Professional | Silicon Drift Detector |

| DELTA Element | Si-PIN Diode Detector | |

| Analytical Range | DELTA Professional | Alloy and Mining: Mg and up for Rh/Ag and Al and up for Ta/Au; Soil: P and higher |

| DELTA Element | Alloy: Ti and higher | |

| Weight | 1.5 kg (3.25 lbs) without battery | |

| Dimensions | 260 x 240 x 90 mm (10.25 x 9.5 x 3.5 in.) | |

| Environmental Temperature Range | -10 °C to 50 °C (14 °F to 122 °F) | |

| Processing Electronics | 530 MHz CPU with integrated FPU with 128 MB RAM; Proprietary Olympus Digital Pulse Processor (DPP) | |

| Power | Rechargeable Li-ion battery; Hot-swap maintains analyzer per during battery charge | |

| Data Display | 32 bit Color QVGA resolution, Blanview transmissive backlit touch screen; 57 x 73 mm (2.25 x 2.9 in.) | |

| Data Storage | 1 GB microSD (stores ~75,000 readings) | |

| Data Transfer | USB |

If you have question you can reach us. Just fill up the form below.